The Complexities of Expiry Date Control

In a previous blog post we talked about yield and how this can be different from company to company and product to product, and for expiry date management this is very similar.

The life of a product or an ingredient can vary greatly, for example making a frozen ready meal or a sterilised sauce the expiry date is normally based on a defined shelf life, and the time period for calculating the expiry date based on the date of production. But if you’re in the life sciences industry producing products from blood, tissue and bones, the life of finished product will be based on the batch with the shortest expiry date.

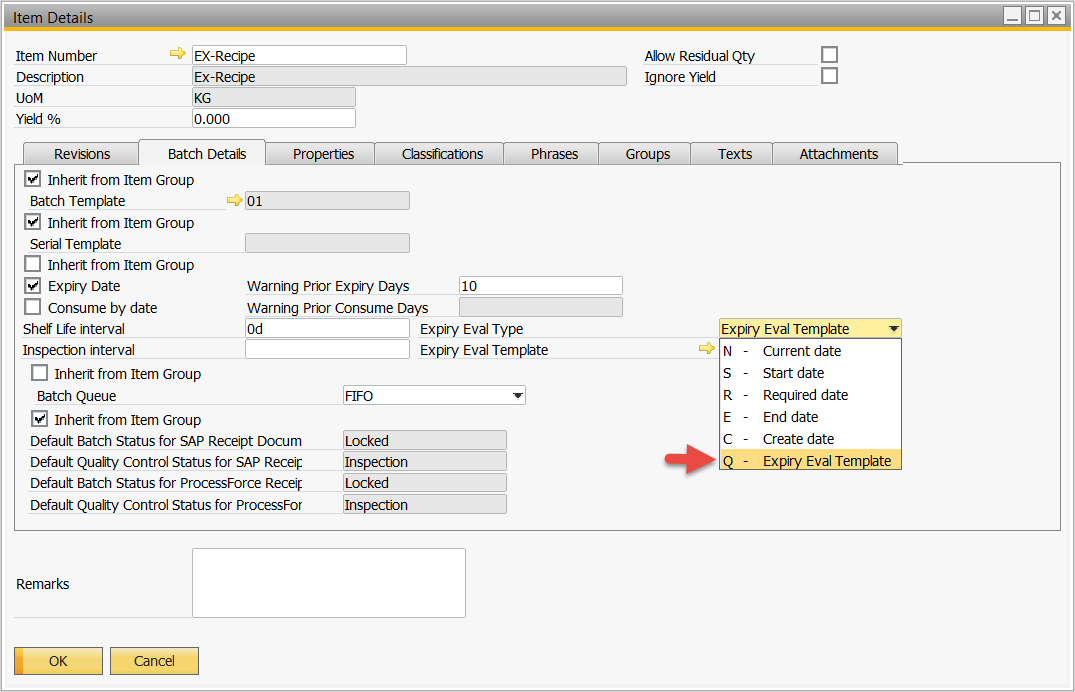

To manage such variation in expiry date calculation ProcessForce provides a number of options to determine the time period of calculation which are illustrated in the screen shot below.

The most complex expiry date calculation, is the expiry date inheritance method otherwise know in ProcessForce as the Expiry Eval Template, which allows the business to determine their rules and methods for managing their inheritance data.The following screens shots provide such an example.

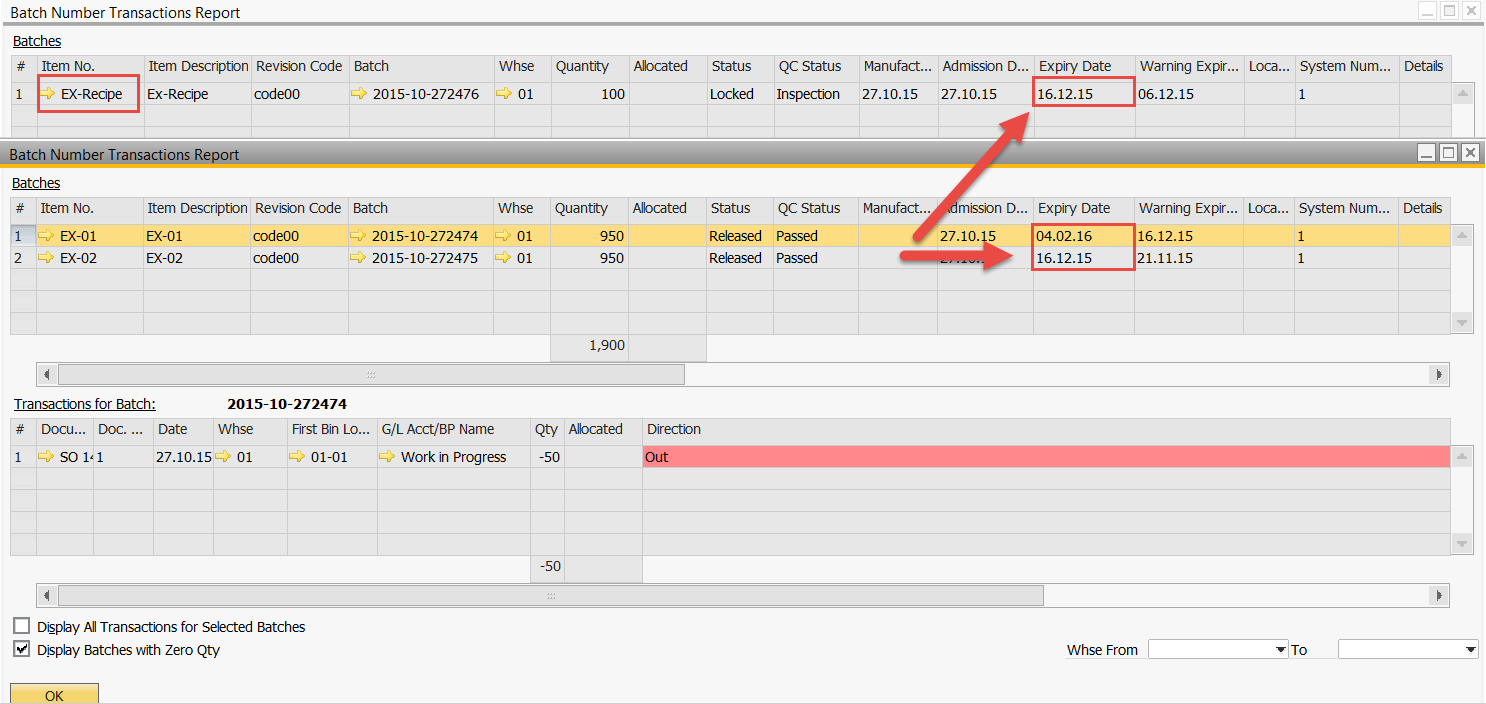

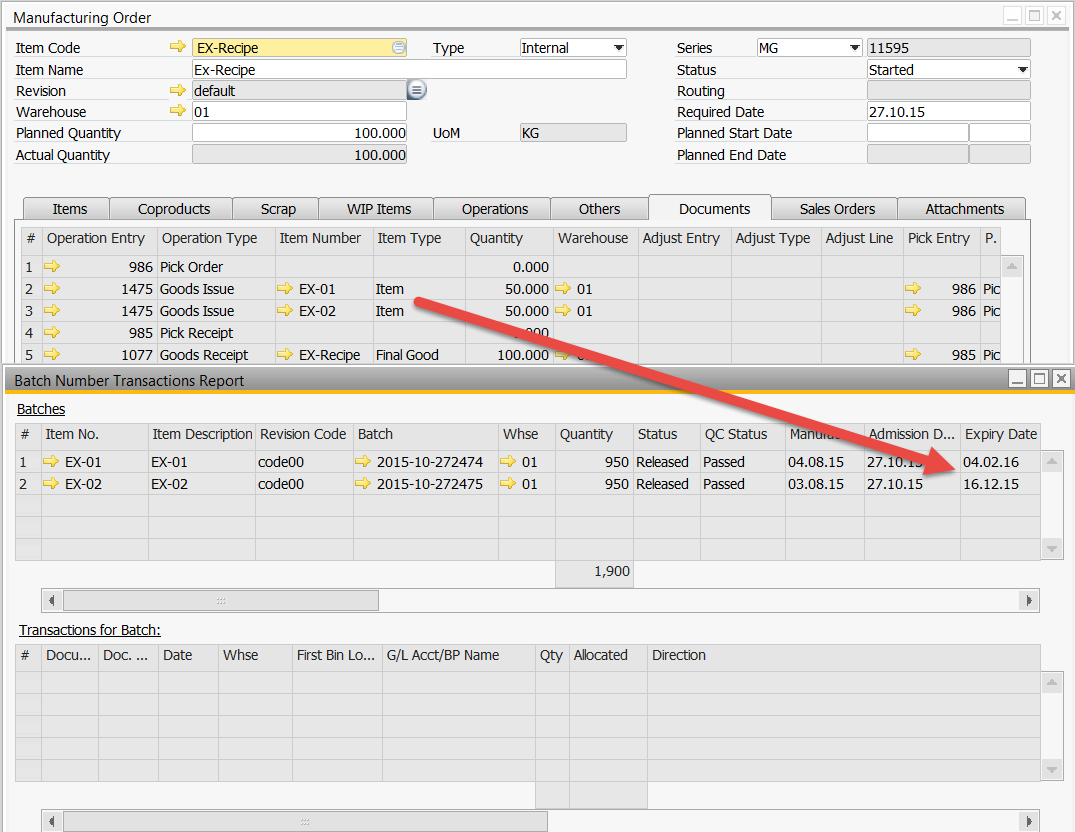

During the production process the manufacturing order consumes two batches of materials, each with a different expiry date, as displayed by the Batch Transaction Report below, with item EX-02 having the youngest date of 16.12.15.

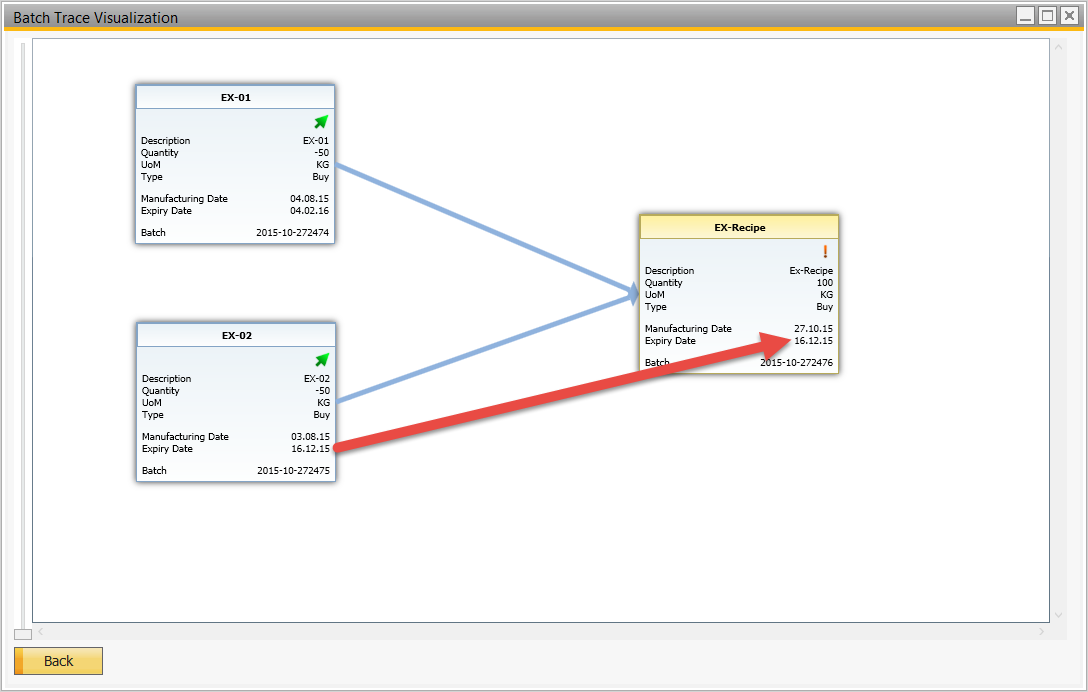

Reviewing the Batch Trace Visualisation diagram clearly displays the traceability of the material batches consumed in the finished product batch, and displays the finished product batch expiry date with the same date as the youngest expiry date of the consumed batche, while the Batch Transaction Report provides additional details.