Yield Planning and Analysis

Yield is a very common requirement across many process and semi-process manufacturing industries and on the surface it looks very simple, but how enterprises manage yield varies considerably depending on the raw materials being consumed, the product or products being produced, and the production process.

Some enterprises plan for yield to increase the amount of specific or all raw materials and production time to be consumed, while others do not plan, but wish to only analyse yield.

In industries such as food and beverage, chemicals and life sciences the raw materials and ingredients being consumed within the recipe or the formulation, may have slight variations across the different batches, such as colour, grade or strength. In this environment how do you manage yield?

For some enterprises they keep it simple, by just comparing the planned vs actual quantity of the product being produced within the manufacturing order. While another enterprise may compare the actual quantity of the produced product vs the consumed amount of a specific raw material or ingredient. While another may compare the produced quantity of coproducts, byproducts and scrap and calculate a separate yield for each of the production outputs.

Yield Planning

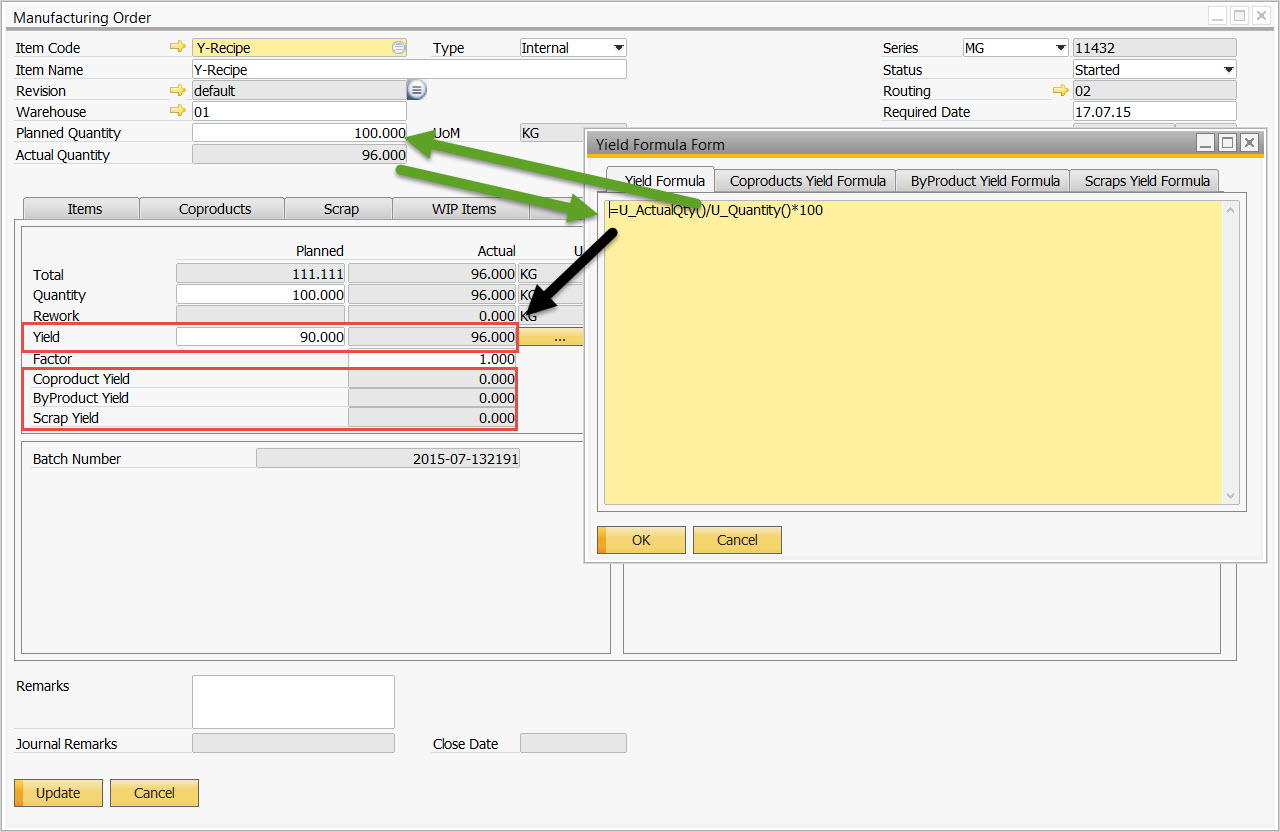

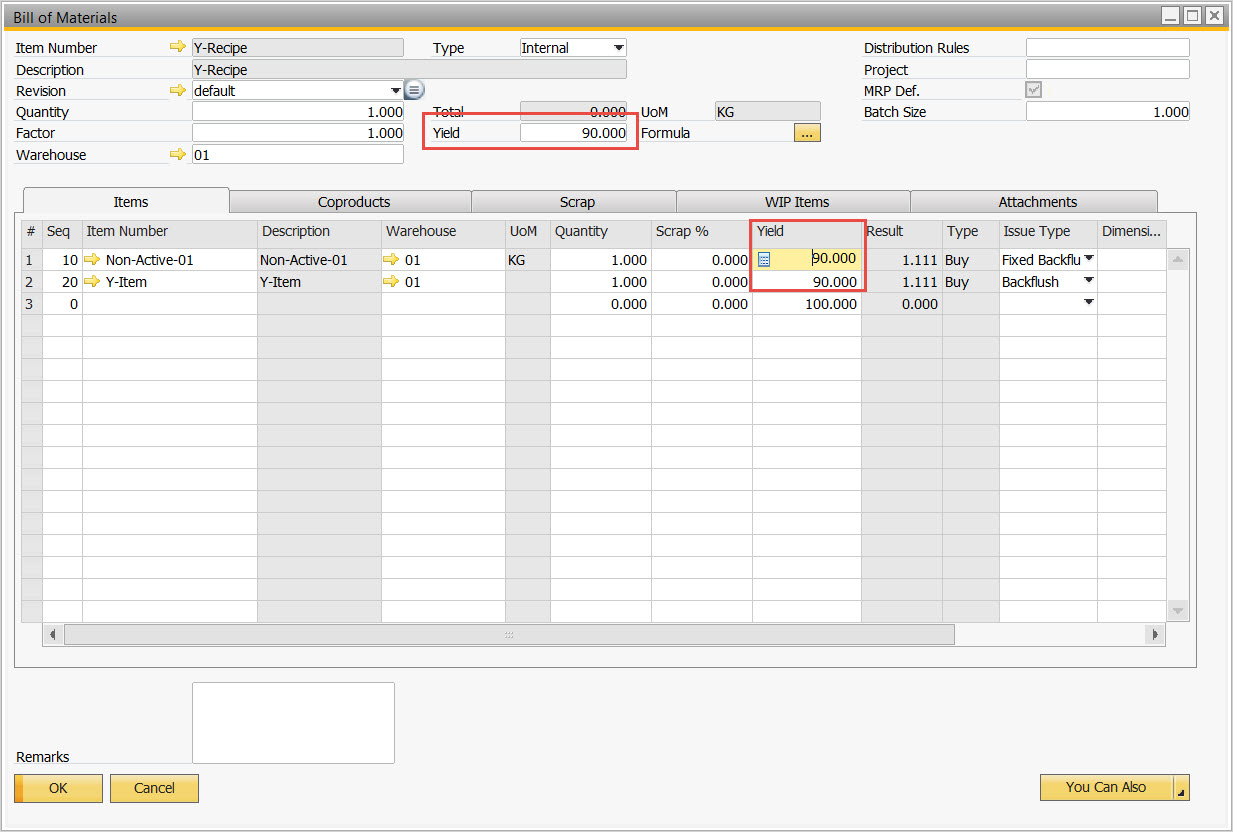

To define the planned yield for a product is a matter of applying a percentage to the recipe or formulation to uplift the raw materials quantities to be issued to production. But for added flexibility an additional yield percentage can be defined at the ingredient level.

Yield Analysis

This is where it starts to get complicated, as there are many different methods in how to determine the actual yield for analysis purposes. The table below provides some different examples.

|

Yield Comparison | |

| Parent Item | Parent Item Planned vs Actual Production Quantity | |

| Parent Item | Parent Item Planned vs Actual Production Quantity – CoProducts - Scrap | |

| Raw Material | Consumed Raw Material(s) vs Actual Parent Item Production Quantity | |

| Raw Material | Consumed Raw Material(s) vs Actual Parent Item Production Quantity - ByProducts - Scrap |

Solution

During most ERP implementations, custom code development is required to meet the customers yield analysis calculation methods. But using the ProcessForce yield ‘formula’ methodology, the customer has full flexibility to define the method in how actual yield is calculated per recipe and formulation, without the need to invest in custom code development, thus lowering the total cost of ownership.