Production Process

Product Routings enables user to define the information required to document and define the production process.Machine control setting and properties such as machine speed, temperate and pressure may also be defined within the routing data, allowing for data integration to MES applications and PLC’s devices.

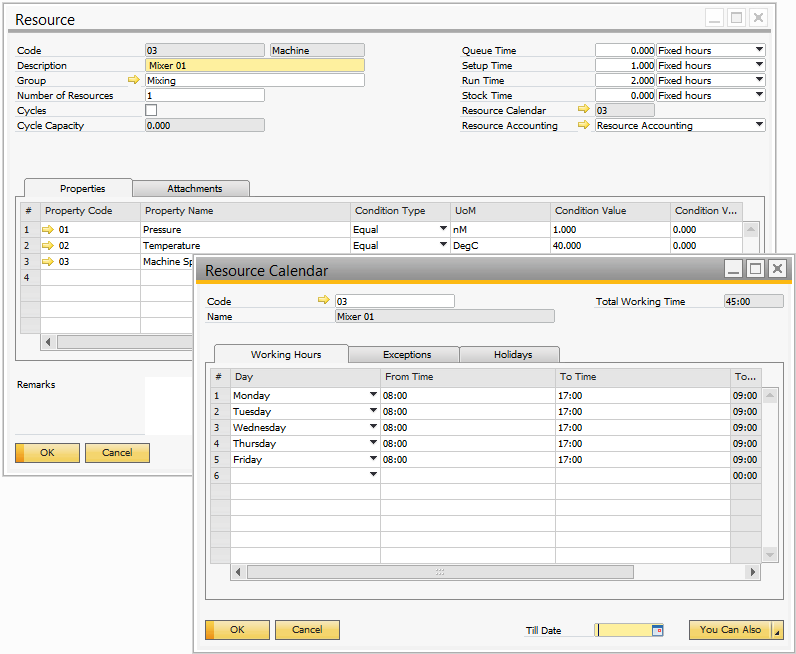

- Resources – define machines, labour and tooling and other such resources that are used in production

- Operations – definition of the production activity

- Routing – the combination of operations and resources to define the total production process

- Properties – define additional information e.g. tooling settings, machine setting such as temperature, pressure, fill rate

- Constraints – define cycle quantity throughput, number of similar machines, and operation to operation overlap based on quantities

- Production time – define queue, set-up, run time, and stock time, each with a different rate of measure e.g. fixed hours, minutes per unit, units per second

- Attachments - to define and link to detailed instructions, procedures, videos and other such media files

- Calendar - define production and resource calendars

- Alternative Routings - define for a product alternative routings

- Duplicate Routings - for ease of use, copy an existing routing and make necessary modifications

- Material / Operation - link the consumption and production of materials to process operations