Solution Hightlight - Subcontract production in the Process manufacturing world

It is common to find food and beverage and pharmaceutical businesses outsource or subcontract part or all of their production processes to a third party.

The brand owner owns the R&D phase of recipe and formulation development and management, and possibly the Quality Assurance and Control, while the subcontractor manages the inventory and production process.

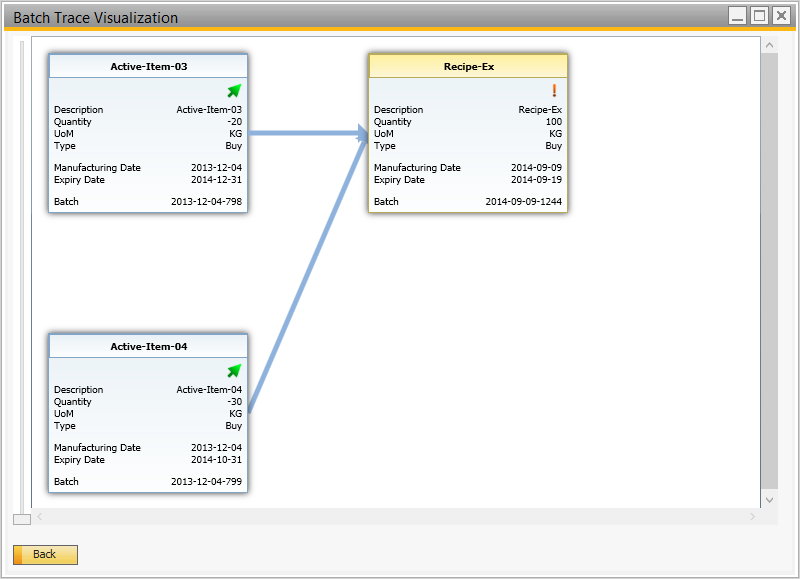

There are many reasons for using a third party to produce and pack goods, but compliance and regulatory requirements still exist for example batch traceability, quality testing and inventory segregation.

So how does ProcessForce manage this?

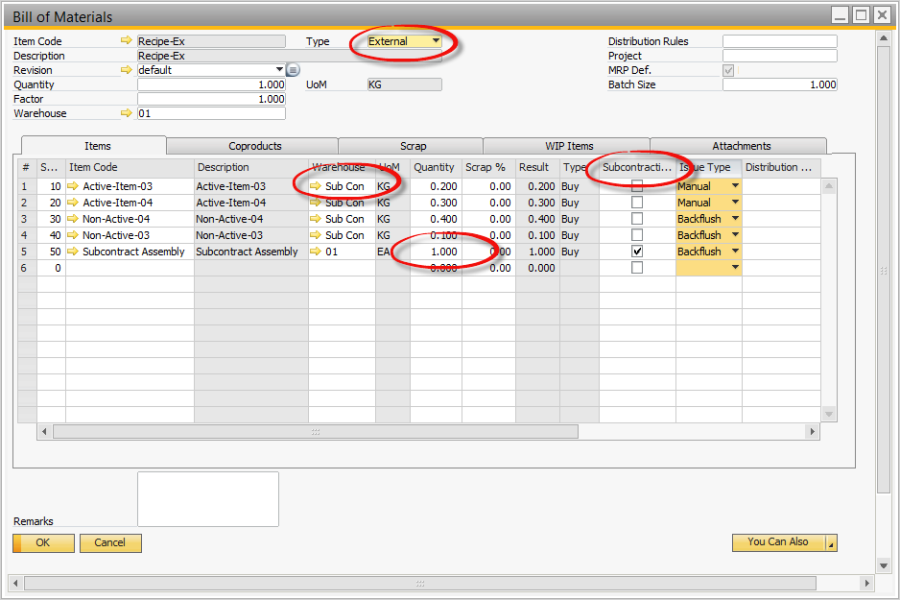

Part 1- Master Data:

- The recipe is marked as “external”

- The warehouse of the free issue materials is the sub-contractors warehouse location.

- Materials can be consumed via backflush (in a traceable world batches are backflushed on a FIFO on FEFO basis) or are manually picked

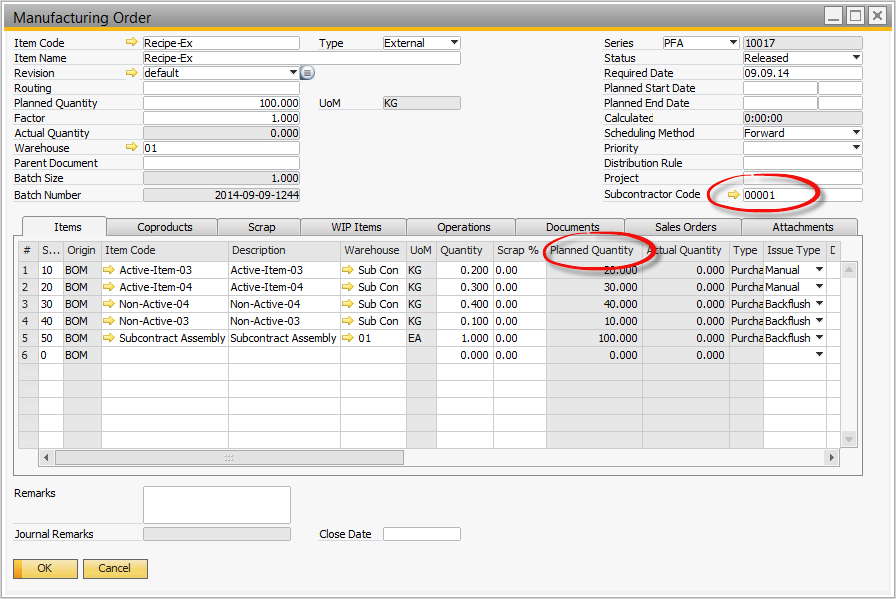

Part 2 - Process and Material flow:

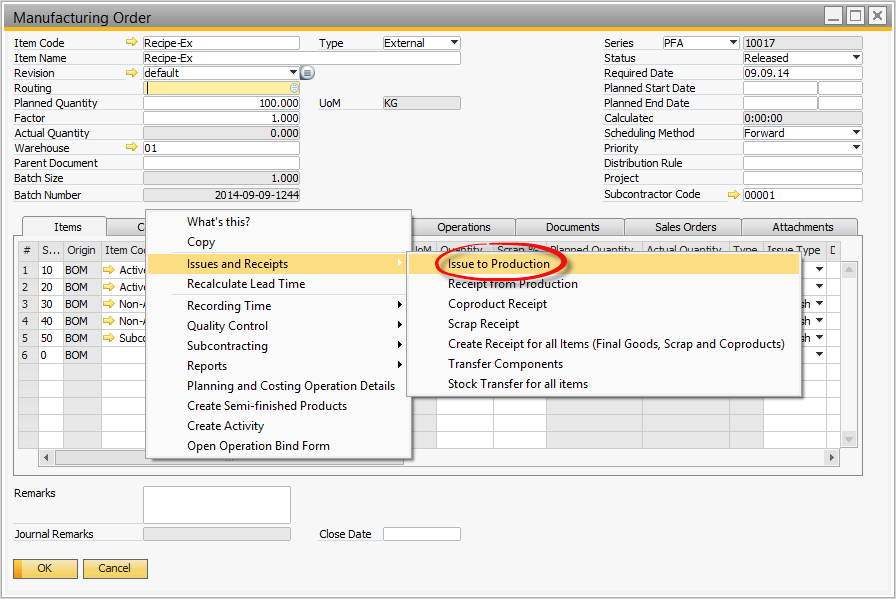

- A manufacturing order is created to manage the subcontract production cycle

- A purchase request or order is created to manage the purchase to accounts payable cycle

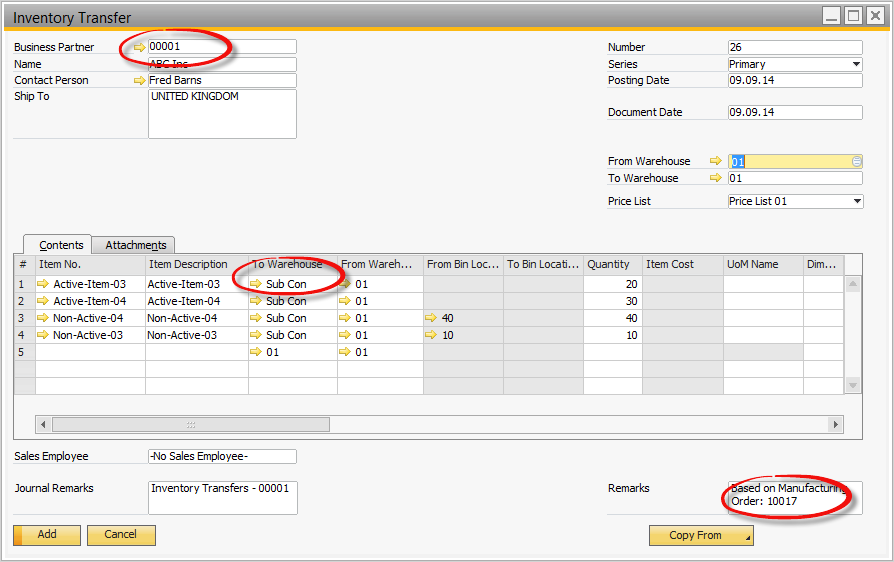

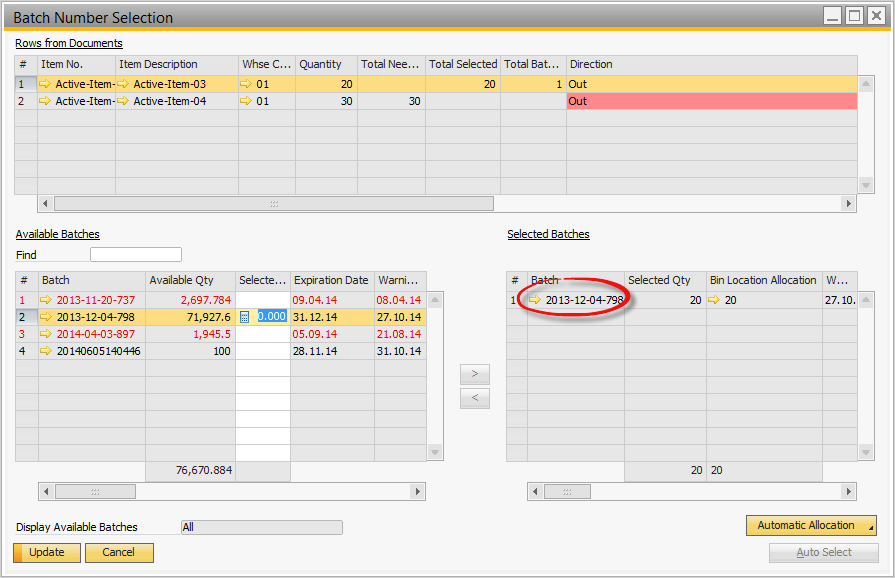

- Stock transfer free issue materials from the brand owner’s warehouse to the subcontractor’s warehouse (or material is purchased and send directly to the subcontractor) with the selected batch numbers

- Record the consumption of the free issue material, with the subcontractor entering the quantity and batch record data directly into the ERP system or barcode scanning) or paper records are passed to the brand owner

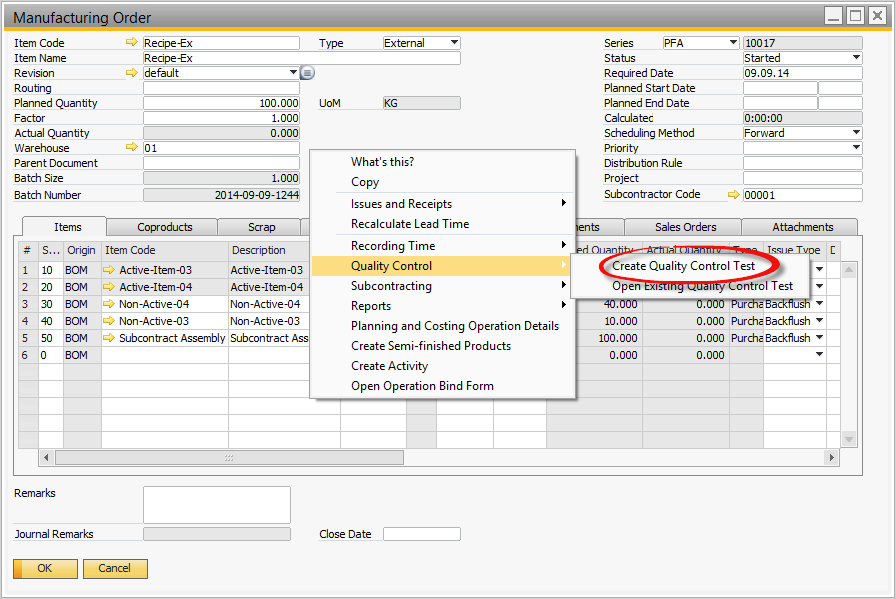

- Perform and record quality control tests for the batch against the manufacturing order

- Record the quantity of the finished product with the corresponding batch number details

- System automatically deduct backflushed based free issue materials (even batch controlled items)

- System automatically creates a Goods Receipt purchase order for the purchase order

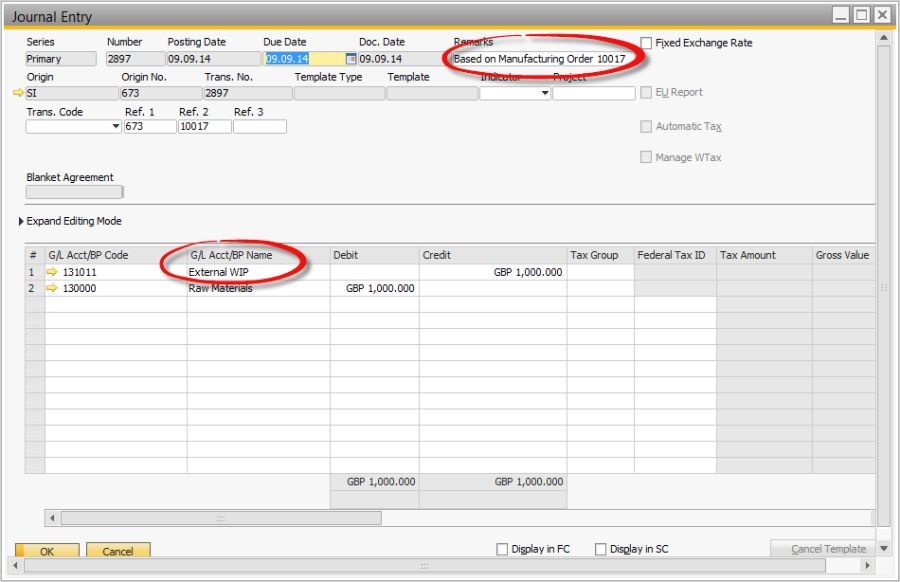

- Financial postings for inventory and external work in progress

The result batch traceability is intact !!