Managing Quality as a core ERP activity within ProcessForce

With ever increasing levels of globalisation, extended supply chains and outsourcing, within regulated environments, integrated quality control solutions within an enterprise’s ERP landscape play an even more important role for todays process orientated manufacturers.

ProcessForce quality control solution, is an easy to use, but flexible addition to the application, providing the tools and necessary processes to manage the quality control functions from purchase goods receipt to customer delivery.

The solution also manages the tests that are required to control and measure products, management via alerts for subsequent transactions and business work flows. Example features and functions include:-

- Test Protocol – define standard templates to be used within the quality control process

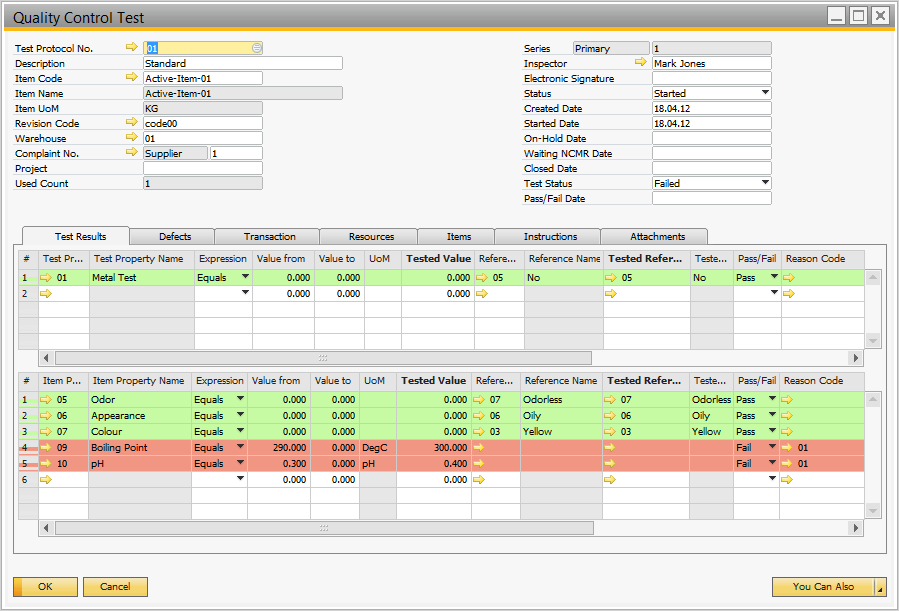

- QC Test – record the activity and results of the tested properties

- Status and Date – manage the QC test cycle

- Non Conforming Materials Report – record specific actions and generate report

- Inspectors – define individuals performing QC activities

- Reason and Defect Codes – define analysis codes and groups for analysis and reporting purposes

- Resources – define the resources to perform the test e.g. microscope, x-ray machine, weight scales

- Items – define the materials that are required to perform the test e.g. gloves, safety glasses

- Frequency – define the frequency and method of testing

- Transactions – define the business process point where the QC test will be performed

- Alerts – business alerts to communicate to inspectors when tests are required to be performed

- Instructions – define instruction steps for performing the test or recording additional notes

- Attachments – to define and link to detailed instructions, procedures, videos

- Warehouse – define tests for a specific warehouse

- Project – define tests as part of a project

- Analysis – dash board and reporting